सीएसआईआर-नीरी परिसर

सीएसआईआर-नीरी परिसर

महाराष्ट्र सरकार के सार्वजनिक निर्माण विभाग (PWD) के इंजीनियरों ने सीएसआईआर- नीरी में जल संसाधन और अपशिष्ट जल प्रबंधन नवाचारों पर प्रशिक्षण प्राप्त किया

महाराष्ट्र सरकार के सार्वजनिक निर्माण विभाग (PWD) के इंजीनियरों ने सीएसआईआर- नीरी में जल संसाधन और अपशिष्ट जल प्रबंधन नवाचारों पर प्रशिक्षण प्राप्त किया

वरिष्ठ शहरी प्रशासनिक अधिकारी मध्य प्रदेश की प्रमुख पर्यावरणीय प्राथमिकताओं के लिए संभावित विज्ञान और प्रौद्योगिकी (एस एंड टी) हस्तक्षेपों का पता लगाते हैं

वरिष्ठ शहरी प्रशासनिक अधिकारी मध्य प्रदेश की प्रमुख पर्यावरणीय प्राथमिकताओं के लिए संभावित विज्ञान और प्रौद्योगिकी (एस एंड टी) हस्तक्षेपों का पता लगाते हैं

श्री शिवाजी विज्ञान महाविद्यालय, अमरावती के बी.एससी. रसायन विज्ञान के 102 छात्रों ने सीएसआईआर-नीरी में विश्लेषणात्मक रसायन विज्ञान एवं पर्यावरणीय निगरानी पर अनुसंधान एवं विकास (R&D) का व्यावहारिक अनुभव प्राप्त किया।

श्री शिवाजी विज्ञान महाविद्यालय, अमरावती के बी.एससी. रसायन विज्ञान के 102 छात्रों ने सीएसआईआर-नीरी में विश्लेषणात्मक रसायन विज्ञान एवं पर्यावरणीय निगरानी पर अनुसंधान एवं विकास (R&D) का व्यावहारिक अनुभव प्राप्त किया।

सीएसआईआर-नीरी द्वारा राष्ट्रीय विज्ञान दिवस 2026 का आयोजन मुख्य अतिथि डॉ. उमा रामकृष्णन की गरिमामयी उपस्थिति में संपन्न हुआ, जिसमें जैव-विविधता, जीनोमिक्स एवं संरक्षण विषयों पर विशेष रूप से प्रकाश डाला गया।

सीएसआईआर-नीरी द्वारा राष्ट्रीय विज्ञान दिवस 2026 का आयोजन मुख्य अतिथि डॉ. उमा रामकृष्णन की गरिमामयी उपस्थिति में संपन्न हुआ, जिसमें जैव-विविधता, जीनोमिक्स एवं संरक्षण विषयों पर विशेष रूप से प्रकाश डाला गया।

सीआरपीएफ 206 कोबरा यूनिट, भंडारा अधिकारी वैज्ञानिक ठोस कचरा प्रबंधन समाधान का पता लगाने के लिए सीएसआईआर– नीरी का दौरा

सीआरपीएफ 206 कोबरा यूनिट, भंडारा अधिकारी वैज्ञानिक ठोस कचरा प्रबंधन समाधान का पता लगाने के लिए सीएसआईआर– नीरी का दौरा

गुजरात फॉरेस्ट रेंज अधिकारियों ने विज्ञान-आधारित वानिकी और पर्यावरण संरक्षण का पता लगाने के लिए सीएसआईआर- नीरी का दौरा किया

गुजरात फॉरेस्ट रेंज अधिकारियों ने विज्ञान-आधारित वानिकी और पर्यावरण संरक्षण का पता लगाने के लिए सीएसआईआर- नीरी का दौरा किया

सीएसआईआर- नीरी ने देशभक्ति की भावना और सतत भविष्य के दृष्टिकोण के साथ गणतंत्र दिवस मनाया

सीएसआईआर- नीरी ने देशभक्ति की भावना और सतत भविष्य के दृष्टिकोण के साथ गणतंत्र दिवस मनाया

सीएसआईआर- नीरी ने चंद्रपुर नगर निगम के लिए एफएसएम हेतु एमडीडीएस प्रशिक्षण का आयोजन किया।

सीएसआईआर- नीरी ने चंद्रपुर नगर निगम के लिए एफएसएम हेतु एमडीडीएस प्रशिक्षण का आयोजन किया।

इंस्पायरिंग यंग माइंड्स: 13वें साइंस एक्सपो, रमन साइंस सेंटर में सीएसआईआर-नीरी

इंस्पायरिंग यंग माइंड्स: 13वें साइंस एक्सपो, रमन साइंस सेंटर में सीएसआईआर-नीरी

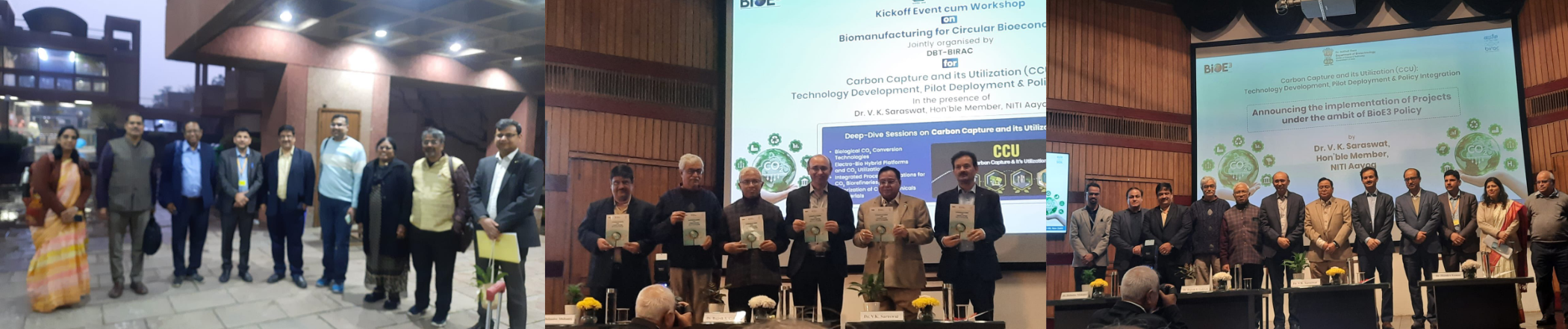

चक्रीय जैव अर्थव्यवस्था के लिए जैव विनिर्माण पर डीबीटी-बीआईआरएसी किकऑफ कार्यक्रम और कार्यशाला: कार्बन कैप्चर और उपयोग

चक्रीय जैव अर्थव्यवस्था के लिए जैव विनिर्माण पर डीबीटी-बीआईआरएसी किकऑफ कार्यक्रम और कार्यशाला: कार्बन कैप्चर और उपयोग